Jun 2, 2022 · The presence of particulate matter (PM) in parenteral drug products is a well-known challenge for pharmaceutical companies due to the potential quality and safety risks involved. In biotherapeutics, critical attributes related to efficacy, potency, clinical safety, and immunogenicity can be affected by PM. 1-3

Minisart ® syringe filters are ideal for clarification of liquids laden with particles, e.g. for preparation of pharmaceuticals or infusion solutions. For sterilization and removal of particles from air and other gases, syringe filters are optimal for sterile venting of containers, bioreactors, fermenters and tubing systems in devices. If you

Jan 1, 2013 · Particulate matter, visible or subvisible, in sterile parenteral products is regarded as a critical quality attribute, impacting safety of the product. Particles can arise from many sources foreign, intrinsic, or inherent to the product, the latter having particular emphasis for biopharmaceuticals. This chapter discusses the nature of these

Nov 20, 2021 · In the past two decades, biopharmaceuticals have been a breakthrough in improving the quality of lives of patients with various cancers, autoimmune, genetic disorders etc. With the growing demand of biopharmaceuticals, the need for reducing manufacturing costs is essential without compromising on the safety, quality, and efficacy of products.

2. Rare reported cases of clinical drift. The greatest testament to the ability of manufacturing and regulatory controls to maintain the consistency and clinical performance of biopharmaceuticals is the paucity of cases where the safety or effectiveness of a biopharmaceutical have changed over time, referred to in this manuscript as clinical drift.

Jan 1, 2015 · In-process tests and controls in biopharmaceutical DP manufacturing are often focused on controls to assure microbial control and sterility, for example, pre-filtration bioburden testing and filter integrity tests. For the same reason stringent facility and procedural controls are required, such as environmental and personnel monitoring.

Mar 11, 2021 · A filter needle (e.g., 19-gauge × 1½-in., 5-μm) is attached to a syringe and the formulation is drawn aseptically into the syringe from the vial. The plunger rod is pulled back sufficiently to ensure the formulation is in the syringe completely before removing the filter needle and replacing it with a needle which will be used for the IVT

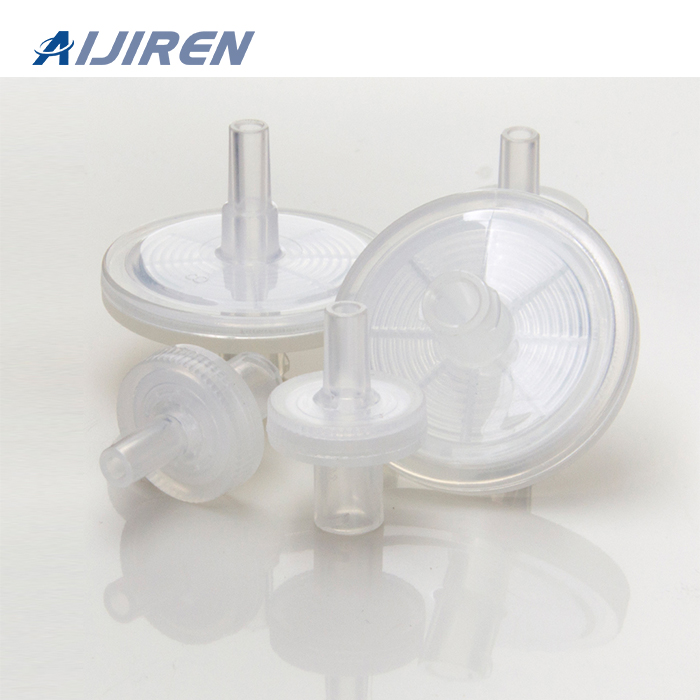

View all products. Cellulose nitrate non-sterile syringe filters. View all products. Depth polypropylene non-sterile syringe filters. View all products. Glass microfiber non-sterile syringe filters. View all products. Nylon non-sterile syringe filters. View all products.

Jul 1, 2023 · Introduction. Protein therapeutics occupy a large share of approved biopharmaceuticals, 1 a growing class of drug products that extends beyond small molecules. 2 Protein biologics are typically administered via injection in multiple forms that include liquids and lyophilized powders, among others. 3 Liquid formulations, which can be filled and transported in different containers (syringes

Oct 16, 2023 · Filtration plays a crucial role in ensuring the safety, efficacy, and quality of biopharmaceutical products. The biopharmaceutical industry uses different filtration systems depending on the type of formulation being purified. These filtration systems use various filter membranes of different sizes.

A CQA is a physical, chemical, biological, or microbiological property or characteristic that should be within an appropriate limit, range, or distribution to ensure the desired product quality. CQAs are difficult to measure directly in production. Along the upstream and downstream portions of the manufacturing process it is most common to

Oct 17, 2023 · The CQAs of a biopharmaceutical product will always include product potency and immunogenicity. Because product-related impurity levels (e.g., aggregated or clipped forms) and other process-related impurities can affect product safety or efficacy, they may also be included in the CQAs for a biopharmaceutical product.

Aug 30, 2023 · Pharmaceutical and Biopharmaceutical Analysis: Syringe filters aid in the purification and sterilization of pharmaceutical products and biopharmaceuticals, ensuring product safety and quality. They are employed in filtration steps during drug formulation and quality control.

Baxter Biopharma Solutions. Syringe manufacturers have responded with PFS systems specifically designed for biotechnology products which have low specifications for tungsten residues, such as BD’s HypakTM for Biotech glass syringe and BD’s SterifillTM COP syringe. The Schott syriQ® InJentle glass staked-needle syringe and West Pharma

Feb 9, 2016 · For instance, depending on the active ingredients, many countries require terminal sterilization of prefilled syringes to ensure the safety of both product and patient. Parenterally administered pharmaceuticals, such as heparin preparations in syringes and infusion solutions in bags or bottles, generally place high demands on the sterility of