Reliable Retention Under All Circumstances. Sartorius virus filtration technology assures the most reliable virus retention even under challenging process conditions. You will benefit from our advanced asymmetric membrane structure that ensures no impact on virus retention through pressure variations, high loads or process interruptions.

(WHO) and the Pharmaceutical Inspection Cooperation Scheme (PIC/s) is expected to come out in 2020 (2). Thus, it is expected to align most regulatory requirements not only for when to perform filter integrity testing, but also on additional considerations such as quality risk management (QRM) throughout the entire pharmaceutical process.

from various commercially available syringe filters (e.g, PES, CA, combination of Glass microfiber as prefilter and the polymer membrane) during filtration of buffer alone and a solution of KGF-2. Besides, the study also evaluated whether preflushing the syringe filter with buffer affected particle shedding into buffer or protein solution during

Quality Risk Management – Some hard Facts •The regulatory focus on QRM is greatly increasing by the arrival of the new Annex1, expected to become effective in 2022 •“QRM” and “Risk Assessment” are mentionedalready in the §-Scope and §-Principle •The word "risk(s)" is used 101 times throughout the latest draft version (Feb 2020)

ICH Q8(R2) Pharmaceutical Development • ICH Q9 Quality Risk Management • ICH Q10 Pharmaceutical Quality System • Draft ICH Q12: Implementation Considerations for FDA-Regulated Products (2021): provide a framework to facilitate the management of post-approval CMC changes, including Appendix A for combination products with device

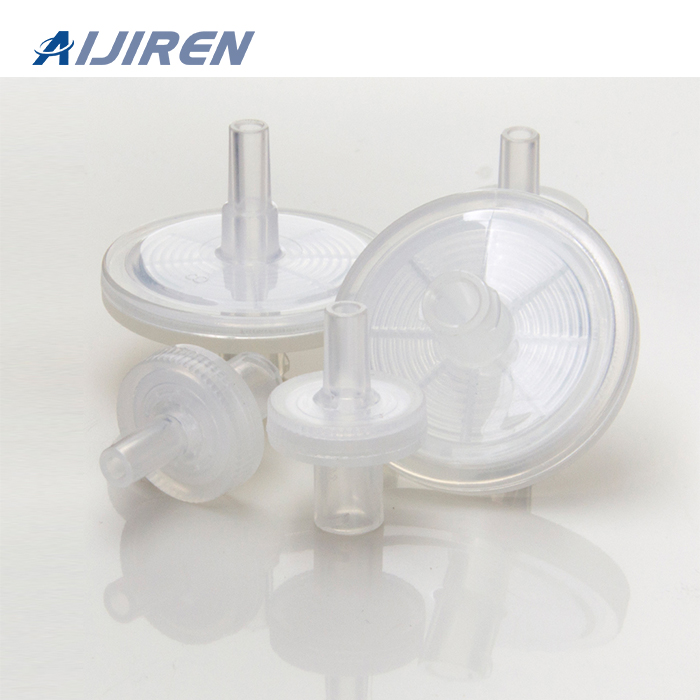

Syringe filters are easy to over-pressurize and may pop off or burst. Several laboratory incidents have occurred in which this has caused a splash to the face. Syringe filters can easily fall off – see Figure 8. If the material is low in hazard, the syringe/filter can be gripped with a closed fist to help contain a splash in the event the

The Sartocheck® 5 Plus Filter Tester is an automatic filter integrity tester with automated Quality Risk Management (QRM) designed to cover the complete range of integrity testing from small syringe filters up to large multi-round housings and tangential flow cassettes.

Feb 7, 2023 · A syringe filter (or wheel filter) is a single-use, membrane-based device used for the removal of particulate impurities from small (≤ 100 mL) liquid samples Selected based upon the desired end application, disposable syringe filters are commonly used in labs for fast and efficient filtering, material purification, or even sterilization.

Aug 22, 2011 · Injection drug use syringe filters (IDUSF) are designed to prevent several complications related to the injection of drugs. Due to their small pore size, their use can reduce the solution's

May 31, 2018 · 1. Develop a robust quantitative view of which risks matter most. Effective risk management begins with a robust process to identify, quantify, and inventory risks, both familiar and new. In this respect, pharma companies can emulate the leading banks that have established clear processes for identifying emerging financial and nonfinancial risks.

Mar 17, 2023 · A syringe filter is a filtering membrane housed in a plastic housing. Either the fluid to be purified can be drawn up the syringe and filtered, or the unfiltered fluid can be pushed through the filter. When analysing a sample with High-Performance Liquid Chromatography (HPLC), Ion chromatography (IC), Gas chromatography (GC), or Inductively Coupled Plasma Spectroscopy (ICP), a Syringe Filter

Feb 28, 2020 · A new business intelligence report released by HTF MI with title "Global Syringe Filter Market Insights, Forecast to 2025" has abilities to raise as the most significant market worldwide as it has

Aug 11, 2019 · X. X. Bolus injection: Filter prior to administration using a sterile, nonpyrogenic, low protein–binding syringe filter. 7. Continuous infusion: Either use a sterile, nonpyrogenic, low protein–binding syringe filter during preparation or administer with an in-line, sterile, nonpyrogenic, low protein–binding filter. 7.

Baxter Biopharma Solutions. Syringe manufacturers have responded with PFS systems specifically designed for biotechnology products which have low specifications for tungsten residues, such as BD’s HypakTM for Biotech glass syringe and BD’s SterifillTM COP syringe. The Schott syriQ® InJentle glass staked-needle syringe and West Pharma

Jun 1, 2016 · One of the fundamental principles guiding the pharmaceutical quality of parenteral products is to prevent injecting contaminants from microbiological, chemical or physical sources. It is just as difficult to ensure the absence of chemical and particulate contaminants in injectable products as it is to weigh up the microbiological risk. The problem of particulate matter is mainly related to the