Oct 24, 2022 · Drug expiration dates reflect the time period during which the product is known to remain stable, which means it retains its strength, quality, and purity when it is stored according to its

through a microbial retentive filter (HEPA minimum) system capable of containing airborne concentrations of the physical size and state of the drug being compounded. Where volatile hazardous drugs are prepared, the exhaust air from the isolator should be appropriately removed by properly designed building ventilation.

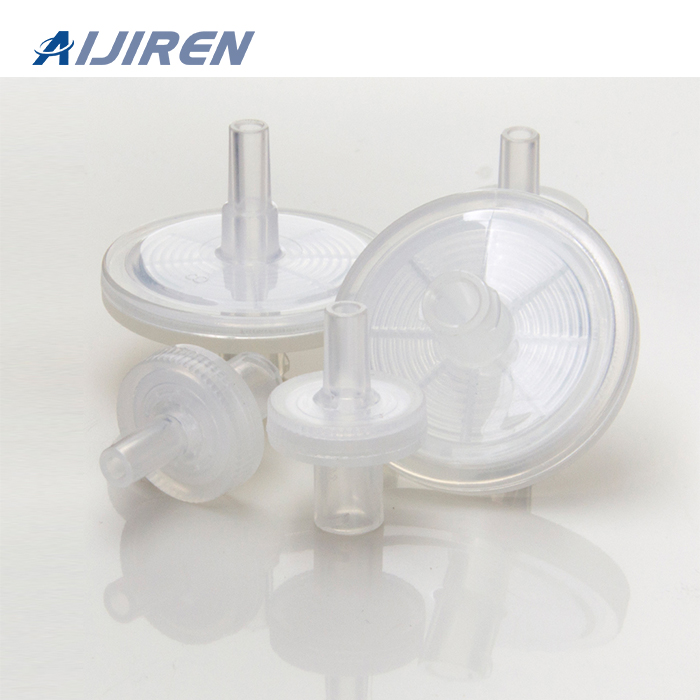

Syringe membrane filter selection and validation methods to assess analyte loss due to membrane filter adsorption in pharmaceutical quality control (QC) testing.

Minisart ® syringe filters are ideal for clarification of liquids laden with particles, e.g. for preparation of pharmaceuticals or infusion solutions. For sterilization and removal of particles from air and other gases, syringe filters are optimal for sterile venting of containers, bioreactors, fermenters and tubing systems in devices.

Dec 20, 2021 · A recent article published in Hospital Pharmacy showed that 93 Intravenous (IV) drugs approved by the FDA between December 2011 and April 2019 require filtration with a syringe or in-line filter (1). Filtration of parenteral formulations (IV drugs) may be required either during preparation of the drug and/or during administration to the patient

Insert the filter needle into the center of the ampule opening. Withdraw the medication from the ampule and verify the fluid level in the syringe. The medications are now mixed. Label the medication syringe. Replace the filter needle with a needleless system or with the appropriate-size needle according to the route of medication.

Using aseptic technique, disconnect the filter needle from the syringe and dispose of it. Do not use the filter needle for injection. STEP 6 . Aseptically and firmly attach the injection needle onto the 1-mL Luer-lock syringe (see Figure 4). Figure 4: STEP 7 Check for air bubbles by holding the syringe with the needle pointing up.

Dec 23, 2022 · BD Syringe Expiration Dates. There is no universally accepted answer to this question as expiration dates on BD syringes can vary depending on the manufacturer and type of syringe. However, it is generally recommended that you consult the BD syringe’s user manual or contact the manufacturer directly for specific expiration date information.

syringe would require estimation of the volume (e.g., measuring 4.5 mL in a 5-mL syringe with no mark at the 4.5-mL level), the use of two sy-ringes of appropriate capacities (or two separate syringe “loads”) should be considered in order to provide a more accurate measurement. c. A fresh disposable needle and syringe should be

Aug 11, 2019 · Bolus injection: Filter prior to administration using a sterile, nonpyrogenic, low protein–binding syringe filter. 7. Continuous infusion: Either use a sterile, nonpyrogenic, low protein–binding syringe filter during preparation or administer with an in-line, sterile, nonpyrogenic, low protein–binding filter. 7.

Dec 28, 2022 · To use a PTFE syringe filter, first, select the appropriate pore size for your liquid. Next, attach the filter to the end of a syringe. Then, draw the liquid through the filter. Finally, remove the filter and dispose of it properly. chromatography columns will last longer if the pore size of the chromatography membrane is 0.45-0.4 micrometer.

1. Assemble a sterile syringe and needle. 2. Hold a 2 mL ampule with an alcohol swab at the neck. Then break the ampule into two pieces away from the person. 3. Insert a 22 gauge needle on the liquid, it should go into the syringe until there is none in the ampule. 4. Turned The syringe with the needle upwards, and all the air ejected until

Nov 22, 2019 · 1. The compounding process involves transfer via sterile needles and syringes of conventionally manufactured sterile allergen products and appropriate conventionally manufactured sterile added substances, and 2. Manipulations are limited to penetrating stoppers on vials with sterile needles and syringes, and transferring sterile liquids

May 14, 2022 · Developing USP General Chapter <797>. USP is a not-for-profit, science-driven organization that has an established process for convening independent experts in the development and maintenance of healthcare quality standards. The process is public health focused, leveraging current science and technology, and draws on the expertise of scientists

Attach the needle to the syringe. Draw air into the syringe equal to the amount of drug to be drawn from the vial. Swab the top of the vial with alcohol before entering the laminar flow hood; allow the alcohol to dry. Puncture top of the vial with the needle bevel up. Bring the syringe and needle straight up, penetrate the