Jun 16, 2014 · For filtration, syringe filters with pore size as large as 0.45 μm have been used for withdrawing supernatant to monitor drug release of small molecules such as Celecoxib . In comparison, high energy separation techniques have been reported with larger biomolecules like Insulin, BSA (Bovine Serum Albumin), and DNA [ 43 , 44 , 48 ].

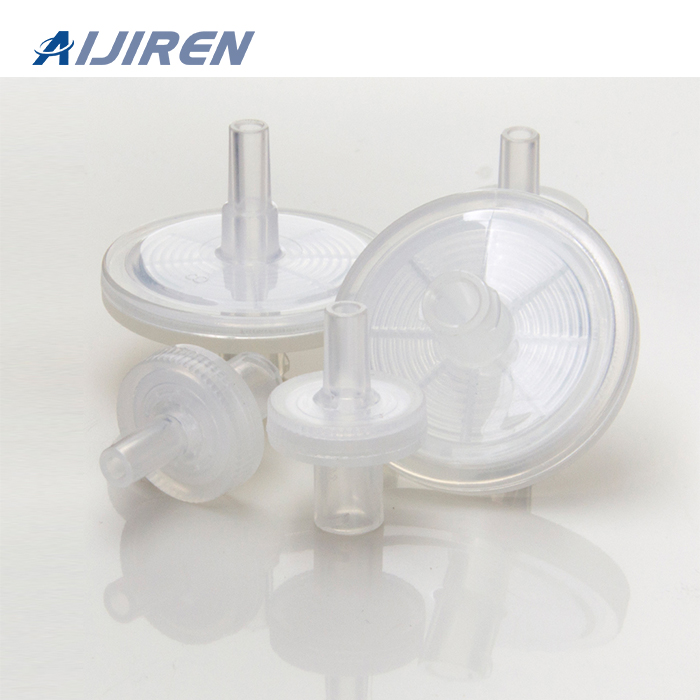

Low protein and drug binding characteristics make it ideally suited for use in life sciences applications. These syringe filters are available as sterile or non-sterile, with or without glass fiber prefilter. *NOTE: Due to high demand, 13 and 25 mm diameter syringe filters are experiencing increased lead times. Resource Literature

Oct 13, 2020 · The easiest method for determining analyte binding to a syringe filter is to filter the sample through it and subsequently collect and analyze various filtrate fractions. Comparing these samples with a centrifuged sample that represents 100% recovery will provide information on analyte binding as well as the volume required for filter saturation.

This exclusive Drug Development & Delivery annual report showcases how leading CDMOs and drug delivery developers are responding to this and other market trends to create ergonomic technologies that are patient friendly, easy to use, reduce needle anxiety, and feature improved packaging materials.

drug’s development and launch is delayed1 Drug development takes a long time Bringing a New Drug to Market is Complex and Costly Drug development is increasingly risky Increasing costs › It can cost $2.6 billion to bring a new drug to market1 › It takes an average of ten years from discovery to market2

Browse All Hydrophobic PTFE Syringe Filters >>. PTFE Hydrophobic Filters Chemical Compatibility Chart >>. PTFE Hydrophilic Syringe Filters 0.2 or 0.45um . Resisting nearly all corrosive chemicals makes PTFE syringe filters an ideal choice. However, natural hydrophobic PTFE has it’s disadvantages not letting aqueous solutions

With the rapid pace of the pharmaceutical industry, sample preparation in drug screening and development is often automated. While this advance in technology saves time and resources, standard syringe filters often fail in automated systems due to high back pressure, filter misalignment, or filter jams due to shingling (Figure 1).

Aug 22, 2011 · Injection drug use syringe filters (IDUSF) are designed to prevent several complications related to the injection of drugs. Due to their small pore size, their use can reduce the solution's insoluble particle content and thus diminish the prevalence of phlebitis, talcosis.

this does not mean that filter validation studies are warranted at this early stage of drug development. Further, FDA Guidance for Industry, INDs for Phase 2 and Phase 3 Studies [3] clearly states that for Phase 2 and 3 Studies, “Information related to the validation of the sterilization process need not be submitted at this time”.

Aug 22, 2011 · Injection drug use syringe filters (IDUSF) are designed to prevent several complications related to the injection of drugs. Due to their small pore size, their use can reduce the solution's

Jan 1, 2019 · The loss of the drug to the syringe filters was expressed as K (%) = (1−Cn/C 0) × 100, where K represents the percentage of the drug lost, Cn is the drug concentration after the syringe filter filtration, and C 0 is the drug concentration in the supernatant of the centrifuged sample without filtration.

Acrodisc™ syringe filters optimized for scale up, a Pall Life Sciences product, contain the same materials of construction as larger-capacity capsules and cartridges to enable easy transition to pilot or full-scale production. Simplifies scale-up and minimizes revalidation; no need to change membrane materials during transition to pilot or

Feb 20, 2013 · Utilization of prefilled syringes as a preferred container closure system for biologics has been increasing [1]. As a primary container closure system, prefilled syringes must provide an integral barrier that protects drug product stability and sterility throughout its entire shelf life. Drug manufacturers are required to check and demonstrate the system is capable of maintaining its microbial

Aug 11, 2019 · This chart is an update to the 2012 article published in Hospital Pharmacy on injectable drugs to be used with a filter. 1 To update the chart (see Table 1 ), drugs approved from December 2011 to April 2019 were reviewed to determine if they require filtration upon preparation or administration.

Jul 16, 2020 · As 1 min may be long in the context of drug use, a shorter stirring time of 20 s was tested with both preparation techniques and 2 filters, the Sterifilt+ and the wheel filter. Preparation of 200-mg capsules : Some people use 200-mg Skenan capsules instead of 100 mg.